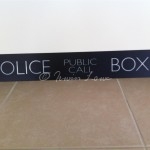

Nerve racking event number two – the light box signs. Being of black vinyl transfer, I was rather conscious of not stuffing these up either by scratching or inadvertantly gluing and then having accident evident stains.

I lined up the centre of the structure gaps, got the clear liquid-nails ready and took a deep breath. Somehow, I imagined that the centre of the signs themselves were in the mid of the “Public Call” bit. Because “police” “box” are different lengths, the centre of the sign is weighted towards the left “P” of “Public”. Good thing I decided to start on the rear panel. Having used the glue several times over a few weeks now, It was quite claggy- slightly beneficial for me as runny would have been worse.

The inverted sign shows how the letters appear bigger when light streams though (flipped for effect).